As the global transition toward sustainable energy accelerates, batteries have emerged as critical enablers of green technologies, powering electric vehicles (EVs), renewable energy storage systems, and countless consumer electronics. Among the most widely used battery chemistries are Lithium-Ion (Li-ion) and Lithium Iron Phosphate (LFP) batteries. Both technologies have revolutionized energy storage, yet their fundamental differences make them suited to distinct applications. Here, we delve into the science behind these technologies, their applications, and how they shape the future of green energy.

Lithium-Ion Batteries: High Energy Density at a Premium

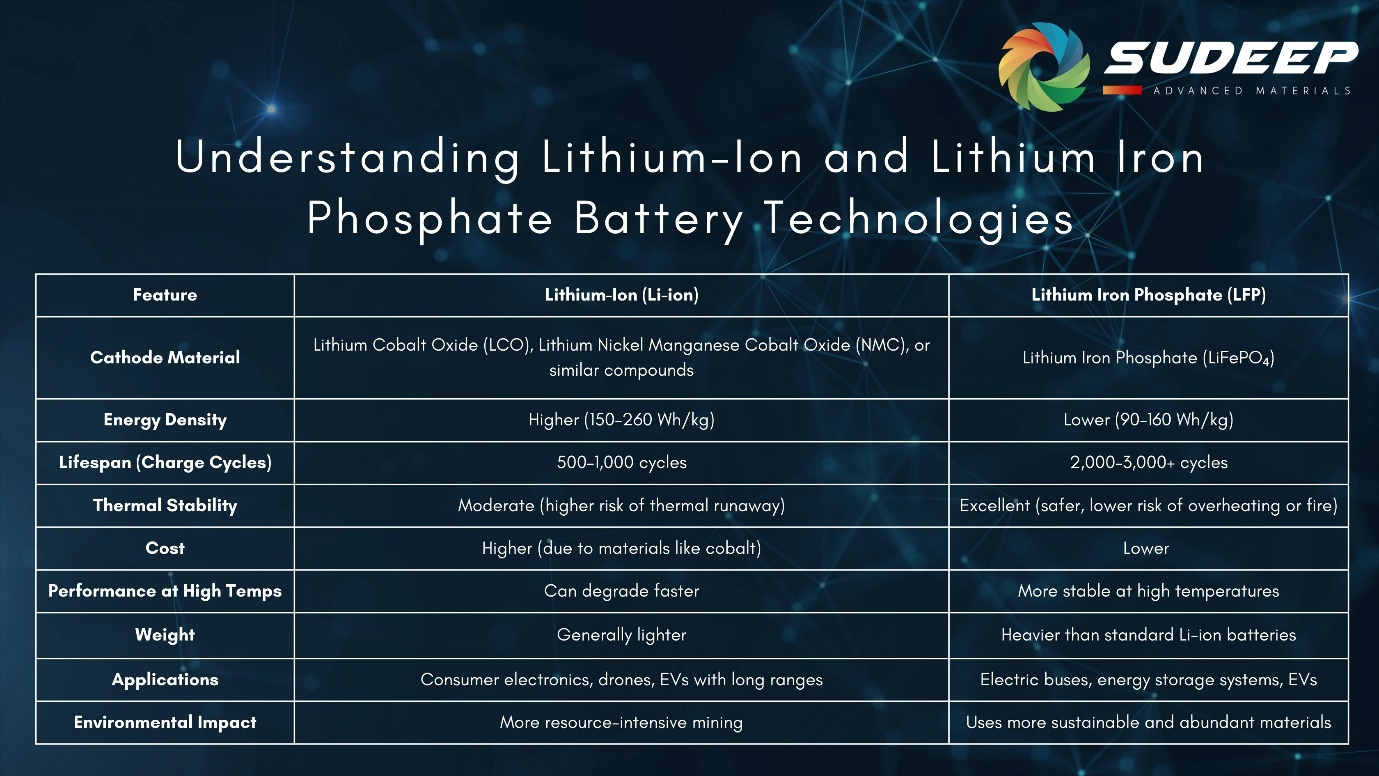

Lithium-Ion batteries are celebrated for their exceptional energy density, which typically ranges from 150 to 260 Wh/kg. This characteristic makes them ideal for applications where weight and space are critical, such as in consumer electronics (smartphones, laptops) and long-range electric vehicles (EVs).

The cathode in most Li-ion batteries is composed of materials like Lithium Cobalt Oxide (LCO) or Lithium Nickel Manganese Cobalt Oxide (NMC). These materials enable high-capacity storage but come with certain trade-offs:

- Safety Concerns:Li-ion batteries are prone to thermal runaway, a phenomenon where overheating can lead to fires or explosions.

- Environmental Impact:Mining and processing cobalt and nickel are resource-intensive and environmentally taxing.

- Cost:The reliance on scarce materials like cobalt makes Li-ion batteries more expensive.

Despite these limitations, Li-ion batteries remain the choice for industries requiring lightweight, high-energy solutions.

Lithium Iron Phosphate Batteries: A Safer, Greener Alternative

On the other hand, Lithium Iron Phosphate (LFP) batteries prioritize safety, longevity, and sustainability. The cathode material in LFP batteries, Lithium Iron Phosphate (LiFePO₄), is inherently more stable due to its robust crystal structure.

Key advantages of LFP batteries include:

- Enhanced Safety:LFP batteries exhibit excellent thermal stability, significantly reducing the risk of overheating or fire.

- Longevity:With a lifespan of 2,000 to 3,000+ charge cycles, they outperform Li-ion batteries in terms of durability.

- Sustainability:Iron and phosphate are abundant and more environmentally friendly compared to cobalt and nickel.

- Cost-Effectiveness:The use of widely available materials makes LFP batteries a more economical choice.

While LFP batteries have a lower energy density (90–160 Wh/kg) than their Li-ion counterparts, they excel in applications where safety, stability, and lifecycle costs are paramount. This includes electric buses, grid energy storage systems, and affordable EVs.

The Role of Precursor Cathode Active Materials (pCAMs)

At the heart of any battery lies its cathode material, and for LFP batteries, iron phosphate serves as a critical precursor. The performance and sustainability of an LFP battery are heavily influenced by the quality and production process of the iron phosphate used.

Sudeep Advanced Materials specializes in the production of high-purity iron phosphate using a green and sustainable manufacturing process. Our innovative technology minimizes waste and reduces carbon emissions, aligning with the global vision of achieving truly green energy solutions. This approach not only enhances the performance of LFP batteries but also reinforces their sustainability credentials, making them an environmentally sound choice for powering the future.

Applications and the Future of Green Energy

Both Li-ion and LFP batteries play indispensable roles in the energy ecosystem. However, the growing emphasis on safety, cost-efficiency, and sustainability has bolstered the demand for LFP batteries, especially in sectors like:

- Renewable Energy Storage:LFP batteries are increasingly used in solar and wind energy systems due to their longevity and ability to withstand extreme temperatures.

- Electric Mobility:Affordable EV models and public transport vehicles like buses prefer LFP batteries for their reliability and safety.

- Industrial Use:LFP batteries are ideal for forklifts, backup power, and other industrial equipment requiring durable energy solutions.

As the world pivots toward green energy, the focus is shifting to technologies that are not just efficient but also environmentally responsible. The production of green iron phosphate, such as that pioneered by Sudeep Advanced Materials, represents a significant step in this direction.

Conclusion: Choosing the Right Technology for a Sustainable Future

Understanding the nuances of Li-ion and LFP battery technologies enables industries and consumers to make informed decisions based on their unique requirements. While Li-ion batteries dominate in energy-dense applications, LFP batteries lead the charge in safety, cost-effectiveness, and sustainability—qualities that resonate with the ethos of a green future.

At Sudeep Advanced Materials, we are committed to advancing battery technology through innovation and sustainability. Our green iron phosphate supports the development of eco-friendly LFP batteries, ensuring that the transition to green energy remains truly sustainable.

Together, let’s power the world with solutions that are not just effective, but truly green